- +91-7077714001

- [email protected]

- 24 X 7 Main Gate Security Help line: 7077714017

- Home

- About

- Institute

- Academics

- Campus and Facilities

- Research and Development

- Training and Placement

- Alumni

Menu

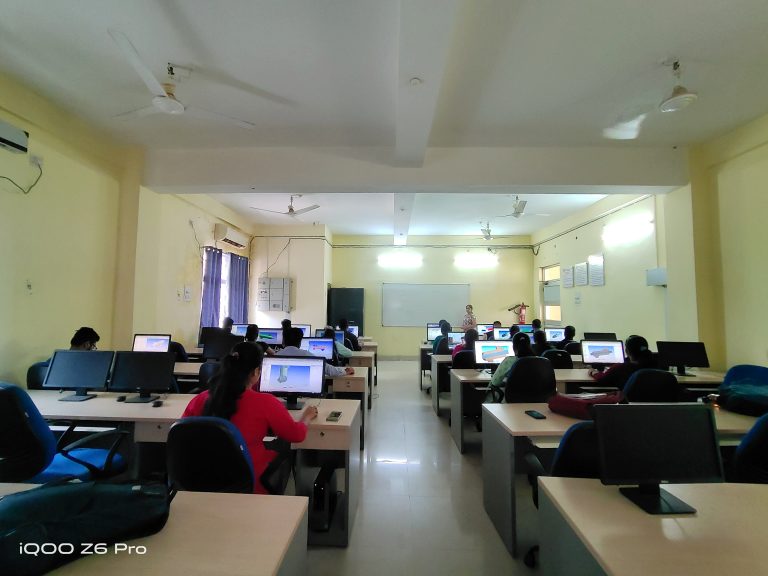

The Department of Chemical Engineering at PMEC is established in the year 2014 with 60 numbers of students. The campus is one of the premier departments in the country that provides a unique educational and research environment. We have a major emphasis on interdisciplinary and industrial collaborations. Our primary missions are to educate graduate students and to discover and disseminate knowledge through research.

The Department is committed to achieving excellence in these activities and evaluates the success and leadership of its programs using the highest standards of quality, innovation, & visibility, while at the same time providing a friendly and supportive atmosphere. Our goal is to provide to our student's strong fundamentals complemented by professional skills including communication. Our other important goal is to produce students and faculty who will become leaders in their areas.

Vision of the Department

To be recognized among highly ranked Chemical Engineering programs of the nation through the pursuit of excellence in teaching and research in all sub-areas of Chemical Engineering and in service to the public.

Mission of the Department

To produce well-trained Chemical Engineering graduates with innovative thinking, knowledge, and skills to excel in postgraduate programs or to succeed in the technical profession and to instill in them the spirit of passion and dedication to work creatively and effectively for the betterment of humankind.

Programme Educational Objectives (PEOs)

| Sl. No. | Programme Educational Objectives |

| 1 | To produce highly qualified, well-rounded, and motivated graduates possessing fundamental knowledge of Chemical Engineering who can provide leadership and service to Odisha, the Nation, and the World |

| 2 | To pursue creative research and new technologies in Chemical Engineering and across disciplines in order to serve the needs of industry, government, society, and the scientific community by expanding the body of knowledge in the field. |

| 3 | To develop partnerships with industry and government agencies. |

| 4 | To achieve visibility by active participation in conferences and technical and community activities. |

| 5 | To publish enduring scientific articles and books. |

Programme Outcomes (POs)

The Chemical Engineering graduates have bright scope of employment in Fertilizer, Petrochemicals, Cement, Metallurgical, Paper, Pharmaceutical & Software Industries. The course structure has been revised in accordance with the need of different industries. To cope with the demand of software engineers, the department is putting extra emphasis on computer-related subjects. The department arranges industrial study tours to make the students acquainted with different industries. The department has one Chemical Engineering Society, which is actively engaged in all total development of the students. This department is also a Student Chapter of the Indian Institute of Chemical Engineers, which is actively involved in various student-related activities.

Welcome to the Department of Chemical Engineering at Parala Maharaja Engineering College (PMEC).

Chemical Engineering is a dynamic and exciting field that lies at the intersection of science, engineering, and technology. Our department is dedicated to providing a comprehensive and stimulating educational experience to aspiring chemical engineers, equipping them with the skills and knowledge required to excel in their careers.

At PMEC, we believe in nurturing a spirit of inquiry, innovation, and problem-solving among our students. Our highly qualified and experienced faculty members bring a wealth of expertise and industry experience to the classroom, ensuring that our students receive a well-rounded education. They are committed to fostering an environment of academic excellence, research, and professional development.

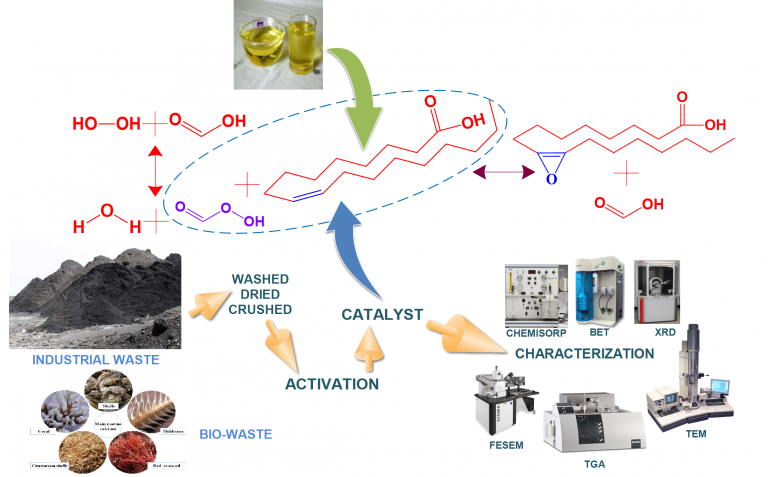

Our curriculum is designed to keep pace with the evolving needs of the chemical industry. We offer a diverse range of courses that cover fundamental principles, advanced topics, and emerging areas of chemical engineering. The curriculum is periodically updated to incorporate the latest advancements in areas such as process optimization, sustainable processes, biotechnology, and nanotechnology. Our goal is to produce graduates who possess a strong foundation in chemical engineering principles and are well-prepared to address the challenges of the industry.

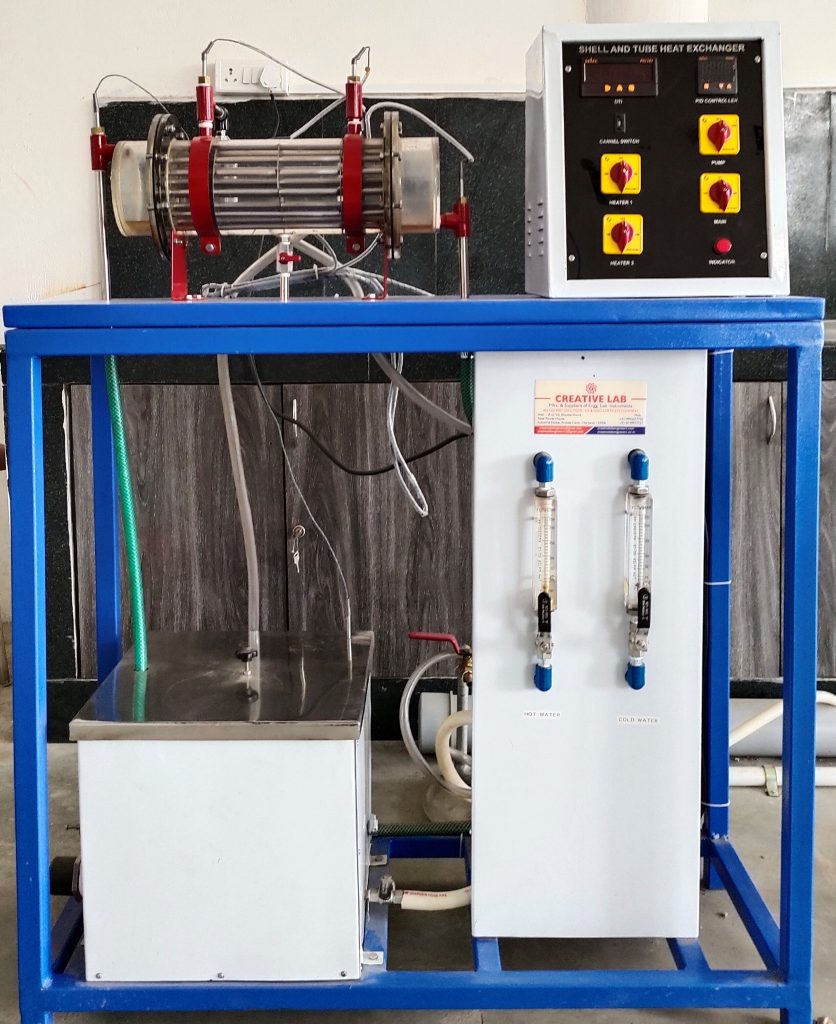

Practical learning is an integral part of our program. We have state-of-the-art laboratories and well-equipped facilities that provide hands-on training and research opportunities to our students. These laboratories enable students to apply theoretical concepts, conduct experiments, and gain valuable insights into industrial processes. We encourage students to actively engage in research projects, internships, and industrial training to enhance their practical skills and broaden their horizons.

In addition to academic excellence, we focus on the holistic development of our students. We provide various platforms for students to showcase their talents, such as technical competitions, national-level conferences, and symposiums. We also encourage participation in co-curricular activities and student organizations that promote leadership, teamwork, and communication skills.

Our department maintains strong ties with the industry, and we actively collaborate with renowned organizations to facilitate industrial visits, guest lectures, and internships. These interactions provide valuable industry exposure and networking opportunities for our students, bridging the gap between academia and the real world.

As you navigate through our website, you will find detailed information about our faculty, laboratories, research initiatives, and other relevant resources. Whether you are a prospective student, a current student, or a visitor seeking information about our department, we hope that our website serves as a valuable source of information.

Please feel free to reach out to us if you have any queries or require further assistance. Our faculty and staff are here to support you and guide you on your educational journey.

Thank you for visiting our website and considering the Department of Chemical Engineering at PMEC. We look forward to being a part of your academic and professional growth.

Best regards,

Dr. Himadri Sahu

Head of the Department (Chemical Engineering)

Parala Maharaja Engineering College (PMEC)

page under construction

Will be updated soon

Parala Maharaja Engineering College, Sitalapalli, Berhampur – Pin-761003, Odisha, India

Copyright © 2023 Parala Maharaja Engineering College. All Rights Reserved.

Designed & Developed By Suryanandan.net